Product

Optical Components (Plastic Lens)

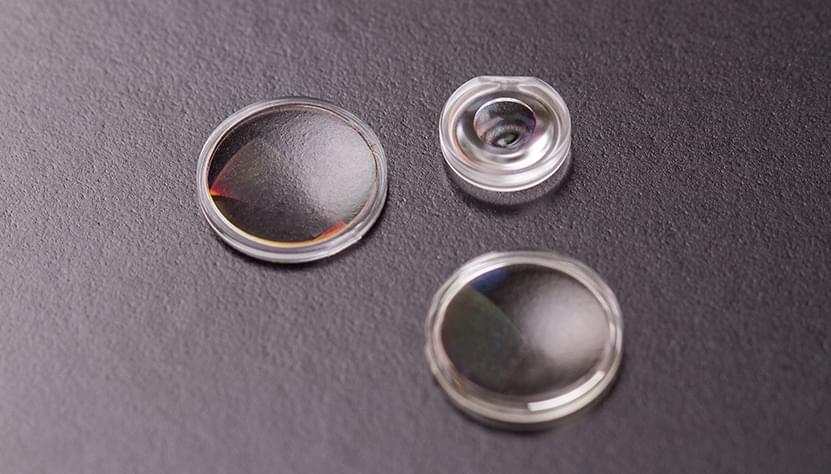

Imaging Lens (Smartphones, Automotive)

Performance requirements for imaging lenses for smartphones are getting more stringent as their imaging devices are aiming for higher resolution. Nissei Technology has established ultra-precision molding technologies to shape the surfaces of the thin multiple lenses that are housed in a small optical tube.

There are high expectations for the sensing cameras for advanced driver assistance systems (ADAS) for autonomous vehicles. Nissei Technology is working on establishing ultra-precision molding technologies and anti-reflection membrane forming technologies that are compatible with temperature-resistant plastic to achieve the high reliability required for imaging lenses for vehicles.

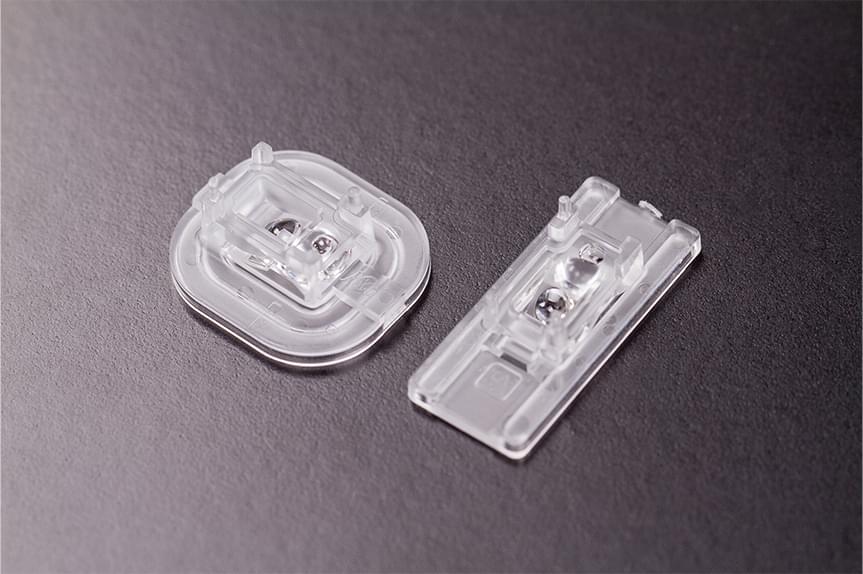

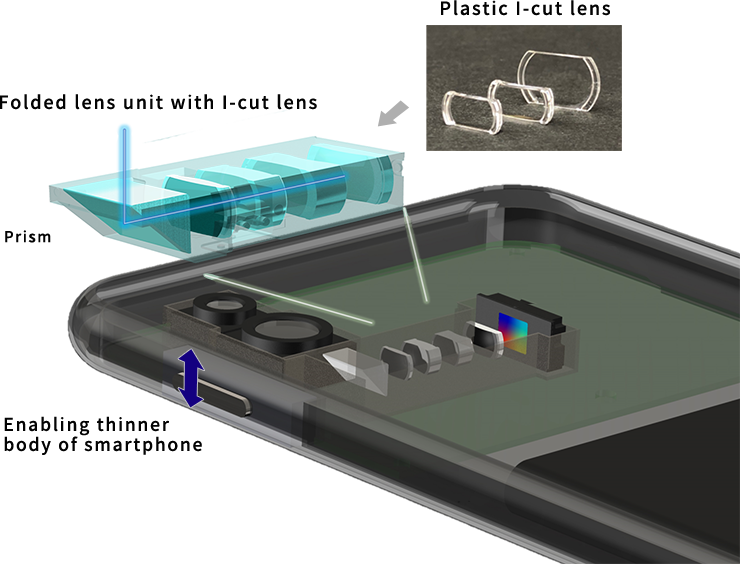

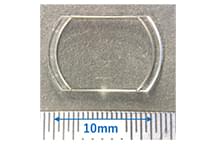

Plastic I-cut lens

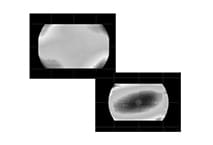

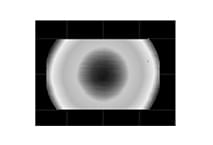

Ultra-precision 3D measurement Data

Tend to occur Astigmatism

(All optical-effective-areas PV 0.5~1.0μm)

General plastic I-cut lens

Ultra-precision 3D measurement Data

Minimize Astigmatism

(All optical-effective-areas PV ≦0.2μm)

Nissei plastic I-cut lens

Our injection molding “Plastic I cut lens” achieves equal or higher surface accuracy than general circular lens

without secondary processing.

※I-cut lens (I cut shape lens)

It is one type of non circular or rectangle lenses and sometimes called “D cut lens” , “H cut lens” or “Double side cut lens”. It is a key component for thickness reduction of optical units.Fresnel Lens

A Fresnel lens has a thin structure that is formed by sections of curved refraction surfaces of a conventional lens.

A Fresnel lens can take the form of a plate. It can also be a hybrid lens with only one side being a Fresnel surface.

We can also produce a plastic aspherical Fresnel lens on one side of a conventional lens.

Free-Curved Surface Lens

A free-curved surface lens is a new technology that expands the range of applications for optical devices. It has been a dream technology for optics engineers and is attracting high expectations from our customers. Free-curved surface lenses can be described in many types of mathematical formulae depending on the application. Nissei Technology customizes our processing programs and surface profile measuring programs according to our customers’ requirements and achieves the products they need with our ultra-precision production technologies.

Cylindrical Lens

A conventional lens is composed of lens surfaces with a rotational symmetry. A cylindrical lens, however, is a special lens with a refractive function only in one direction of its cross section. We apply ultra-precision mold processing technologies to form a mold to make an ultra precise cylindrical surface. Our ultra-precision mold forming technologies and generatrix angle measuring technologies realize major components in our overseas plants for laser beam printers.

Sensor Lens

As our society demands more for security and IoT, there is a requirement for high-performance sensing lenses for detection and measurements such as person recognition, person detection, person counter, and contactless temperature measurement. Nissei Technology is working from optical design to mass-production considering the optical characteristics of infrared transmitting plastic materials to satisfy our customers’ specifications.